Introduction

The hand lay-up process is crucial in composite material manufacturing, known for its versatility and cost-effectiveness. It's especially favored in industries like marine, automotive, and aerospace, where durability and performance are paramount. At the core of this process is General Purpose Resin, a material that provides both rigidity and mechanical strength, making it ideal for various applications.

In this article, we’ll explore why General Purpose Resin is often the best choice for hand lay-up. We will cover its key advantages, diverse applications, and best practices to achieve superior results in composite manufacturing.

Understanding General Purpose Resin and Its Role in Hand Lay-Up

What is General Purpose Resin?

General Purpose Resin is a type of polyester resin used widely in composite manufacturing, particularly in hand lay-up processes. It consists of unsaturated polyester resin, which is combined with a hardener to initiate curing. This resin is typically reinforced with materials such as fiberglass or carbon fiber to enhance its strength and stiffness.

The composition of General Purpose Resin provides a balance between ease of use and superior mechanical properties, making it a staple in the production of lightweight, durable composite parts.

Why General Purpose Resin is the Ideal Choice for Hand Lay-Up

The versatility of General Purpose Resin makes it a top choice for hand lay-up, as it is compatible with various reinforcement materials like fiberglass and carbon fiber. Its inherent ability to cure at room temperature makes it practical for a range of applications, from marine boat hulls to automotive body parts.

The resin's ability to deliver consistent mechanical strength and rigidity ensures that composite materials remain durable and reliable in demanding conditions. Whether for small runs or large structural components, General Purpose Resin excels in producing strong, lightweight materials without the need for high-tech automated machinery.

Feature | Benefit |

Versatility | Compatible with fiberglass, carbon fiber |

Room Temperature Cure | Ideal for various applications |

Mechanical Strength | Provides durability and reliability |

Lightweight | Strong materials without automation |

Advantages of General Purpose Resin for Hand Lay-Up

General Purpose Resin offers several advantages:

● Mechanical Strength: Once cured, it provides excellent tensile and flexural strength, making it ideal for products that need to withstand stress.

● Ease of Application: It’s easy to handle and apply manually, which is critical for the hand lay-up process.

● Cost-Effectiveness: Compared to other resins like epoxy, General Purpose Resin is more affordable, making it an ideal choice for budget-conscious manufacturers.

The Hand Lay-Up Process: Step-by-Step Guide to Achieving Superior Results with General Purpose Resin

Preparing the Mold and Materials

Before you begin the hand lay-up process, proper mold preparation is crucial. The mold should be clean, dry, and treated with a release agent to facilitate easy removal of the cured part. Additionally, choosing the correct reinforcement materials—whether fiberglass, carbon fiber, or a combination—is key to achieving the desired strength and rigidity in the final product.

Tip: Ensure the mold is free of any dust, debris, or contaminants to avoid defects in the final composite.

Application of General Purpose Resin in Hand Lay-Up

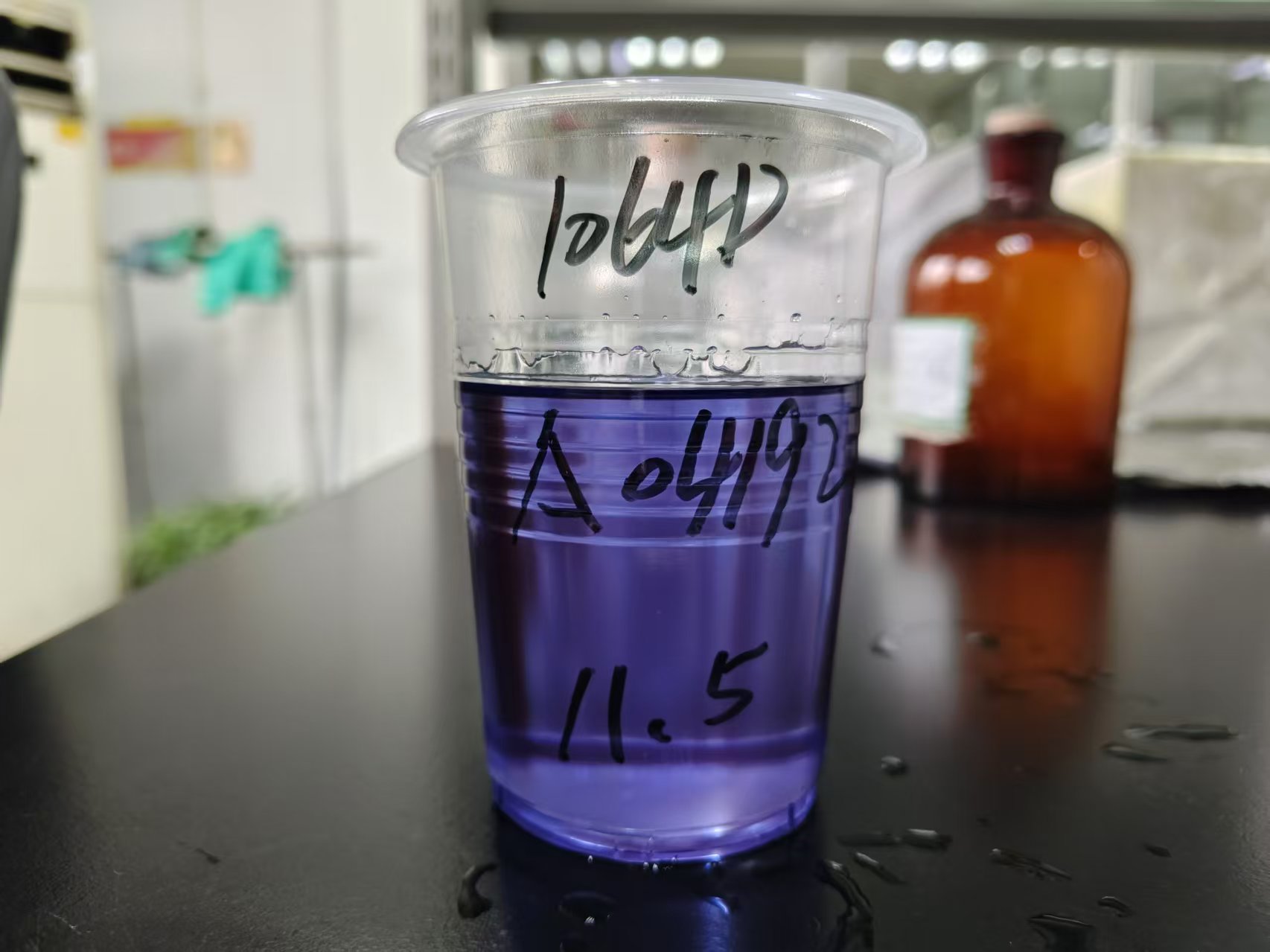

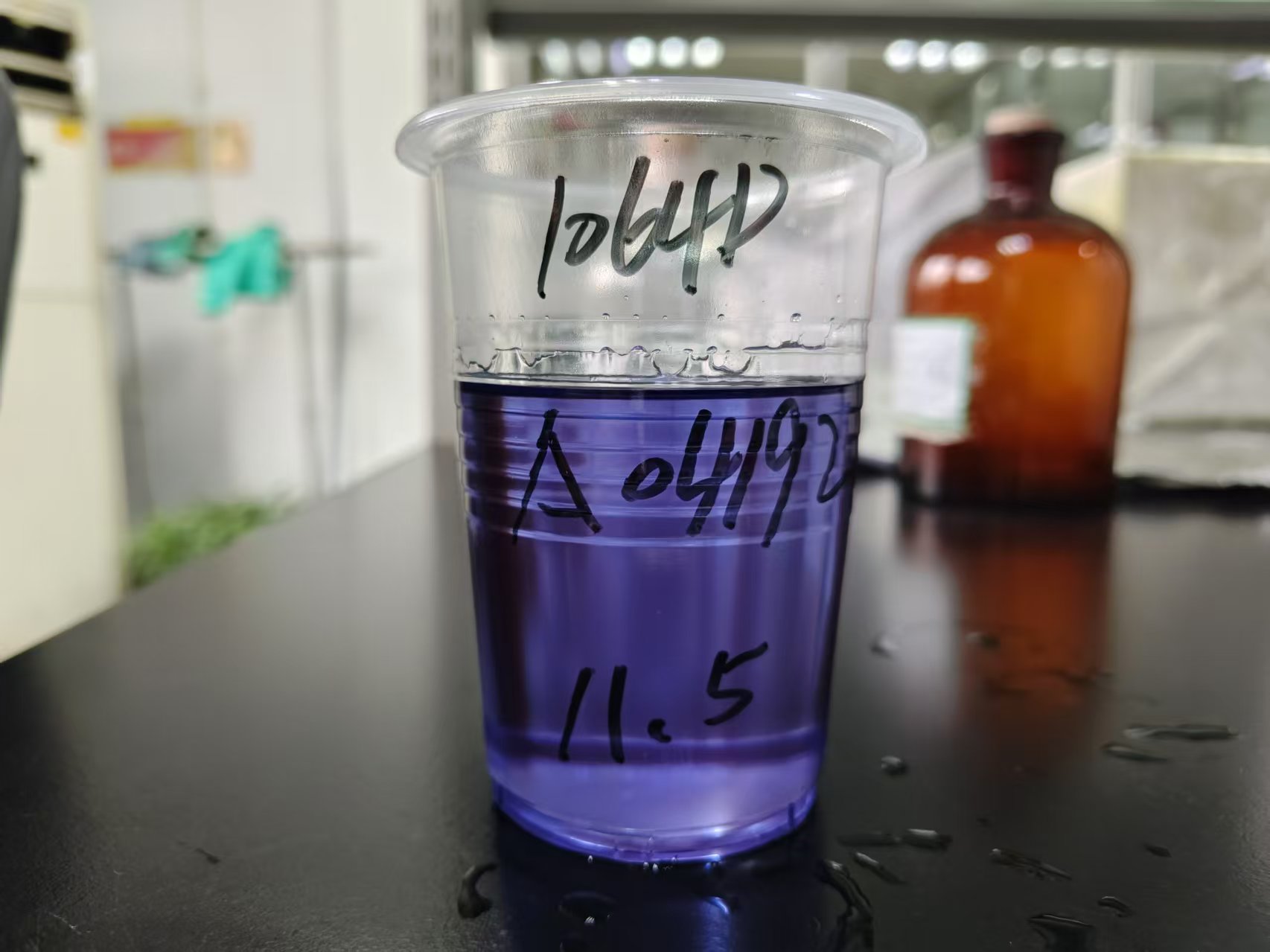

The application of General Purpose Resin begins by mixing the resin with its hardener. Once mixed, the resin is applied evenly to the reinforcement materials, typically using a brush, roller, or spatula. The goal is to ensure that the resin thoroughly saturates the fibers for maximum bonding and strength.

Tip: Apply resin in thin, even layers, allowing each layer to partially cure before applying the next. This ensures better adhesion and reduces the risk of air entrapment.

Curing Process and Final Inspection

Once the resin is applied, the curing process begins. The curing time can vary depending on temperature and the type of hardener used, but it's crucial to follow the manufacturer’s guidelines. Proper curing ensures the final product achieves its full mechanical strength.

After curing, inspect the composite part for any defects like voids or delaminations. These can affect the strength and durability of the final product.

Tip: Allow adequate time for the resin to cure fully, even if the surface appears solid. Post-curing at elevated temperatures may be necessary to achieve optimal properties.

Step | Key Action |

Mold Preparation | Clean, dry, and apply release agent |

Resin Application | Mix resin and hardener; apply evenly |

Curing & Inspection | Follow curing guidelines and inspect for defects |

The Key Benefits of Using General Purpose Resin for Rigidity and Strength in Hand Lay-Up

Enhanced Mechanical Properties

One of the primary reasons General Purpose Resin is chosen for hand lay-up is its ability to deliver superior mechanical properties. Once cured, General Purpose Resin provides excellent rigidity and strength, making it ideal for parts that need to withstand heavy loads and stress. Its strong bonding capabilities ensure that composite materials maintain their integrity over time.

Examples:

● Aerospace: Components like fuselage panels benefit from General Purpose Resin’s strength and rigidity.

● Marine: Boat hulls and marine panels require high resistance to stress and harsh environments, where this resin excels.

Cost-Effectiveness and Flexibility

Another advantage of General Purpose Resin is its cost-effectiveness. Compared to other resins like epoxy, General Purpose Resin is more affordable while still offering high-quality results. This makes it an excellent choice for small to medium production runs where cost control is essential.

Its flexibility also allows manufacturers to create custom products for a variety of industries, from boats to automotive parts, with tailored structural properties.

Customization of Structural Properties

One of the key advantages of hand lay-up is the ability to customize composite materials. Technicians can adjust laminate thickness, fiber orientation, and resin application to meet specific performance requirements. With General Purpose Resin, this customization can help optimize specific areas of the product for high-stress applications.

Benefit | Key Features |

Enhanced Mechanical Properties | Provides rigidity and strength for heavy-duty applications |

Cost-Effectiveness | Affordable compared to other resins like epoxy |

Flexibility & Customization | Tailored solutions for various industries like aerospace and marine |

General Purpose Resin in Different Applications: Industries Benefiting from Its Strength

Marine Industry: Boat Hulls and Other Composite Parts

In the marine industry, General Purpose Resin is used to manufacture boat hulls, marine panels, and other structural parts that need both rigidity and durability. Its cost-effectiveness makes it ideal for small to medium-sized boat manufacturers who require both strength and a reasonable production cost.

Automotive Industry: Lightweight and Strong Components

Automotive manufacturers often use General Purpose Resin for producing body panels and structural components. The resin provides the necessary rigidity while keeping the parts lightweight, an essential factor in improving fuel efficiency and performance.

Aerospace and Industrial Applications

In aerospace and industrial sectors, General Purpose Resin is used for components that need high rigidity and mechanical strength, such as structural panels and other load-bearing parts. Its ability to maintain structural integrity under stress makes it an ideal choice for these demanding applications.

How to Maximize the Potential of General Purpose Resin in Hand Lay-Up

Optimizing Resin Mixture and Application

To achieve the best results, it’s essential to mix General Purpose Resin and its hardener properly. Incorrect mixing can result in improper curing or a weaker final product. Additionally, applying the resin evenly and ensuring it saturates the reinforcement materials is key to achieving a strong composite.

Tip: Always follow the manufacturer’s guidelines for mixing ratios and working time to avoid inconsistencies in the final product.

Curing Tips and Post-Curing Considerations

The curing process is critical for the mechanical strength of General Purpose Resin. Ensuring that the resin cures fully will prevent defects like cracking or poor adhesion. Post-curing at elevated temperatures can further enhance the resin’s properties, ensuring the final product performs well under stress.

Comparing General Purpose Resin with Other Resin Types in Hand Lay-Up

Polyester vs. Epoxy Resins: Which is Better for Hand Lay-Up?

General Purpose Resin (polyester) is often preferred over epoxy resin in hand lay-up due to its cost-effectiveness and ease of application. While epoxy offers superior mechanical strength, polyester resins like General Purpose Resin are better suited for applications that do not require the absolute highest strength but still demand high rigidity.

Resin Flexibility: Customization for Various Needs

Both General Purpose Resin and epoxy resin offer the ability to customize composite materials, but General Purpose Resin is easier to handle and provides a more flexible solution for low-to-medium production volumes.

Comparison Factor | General Purpose Resin | Epoxy Resin |

Cost | More affordable | Generally more expensive |

Mechanical Strength | High rigidity but lower strength than epoxy | Superior mechanical strength |

Flexibility | Easier to handle, flexible for small to medium production | Less flexible, better for high-performance parts |

Customization | Easier to customize for various applications | Customizable but more complex handling |

Conclusion

General Purpose Resin is the ideal choice for hand lay-up, offering a perfect balance of mechanical strength, rigidity, and cost-effectiveness. Its versatility across industries like marine, automotive, and aerospace makes it essential for manufacturers seeking durable and lightweight composite parts. By optimizing resin mixtures, application techniques, and curing processes, manufacturers can achieve high-quality results. At Changzhou Huake Polymer Co., Ltd., their innovative products provide exceptional value, ensuring reliable, high-performance composites for a wide range of applications.

FAQ

Q: What is General Purpose Resin?

A: General Purpose Resin is a polyester resin used in hand lay-up processes, providing rigidity and mechanical strength for composite materials.

Q: How is General Purpose Resin applied in hand lay-up?

A: General Purpose Resin is applied to reinforcement materials like fiberglass or carbon fiber to ensure even coverage and optimal bonding during the hand lay-up process.

Q: Why should I use General Purpose Resin for hand lay-up?

A: General Purpose Resin offers an excellent balance of mechanical strength, rigidity, and cost-effectiveness, making it ideal for industries requiring durable, lightweight composites.

Q: What industries benefit from General Purpose Resin?

A: Industries such as marine, automotive, and aerospace benefit from General Purpose Resin, where strength and durability are essential for performance.

Q: How does General Purpose Resin compare to other resins?

A: Compared to other resins like epoxy, General Purpose Resin is more affordable and offers sufficient strength for many applications, making it ideal for low-volume production.